Phenolic paper sheets are a kind of board composed of phenolic resin and paper, which has the characteristics of fire prevention and heat preservation. Phenolic resin is a kind of thermosetting plastic and phenolic foam material is made by foaming process, and then further processed into phenolic paper sheets. Phenolic paper sheets are widely used in developed countries, especially in construction, transportation, aerospace and other fields.

Phenolic cotton cloth sheets are a kind of board made of phenolic resin and cotton cloth. It is made by soaking cotton cloth with phenolic resin, drying and hot pressing. Phenolic cotton cloth sheet has good electrical and mechanical properties. It is suitable for machinery, motors, electrical equipment as an insulating structural parts and can be used in transformer oil.

First, the raw materials for the production of phenolic paper sheets and phenolic cotton cloth sheets are different.

Phenolic paper sheets is made of wood fiber or plant fiber through impregnation, drying, hot pressing and other processes. The phenolic cotton cloth sheet is made of organic cotton fiber and phenolic resin, which are mixed and compressed.

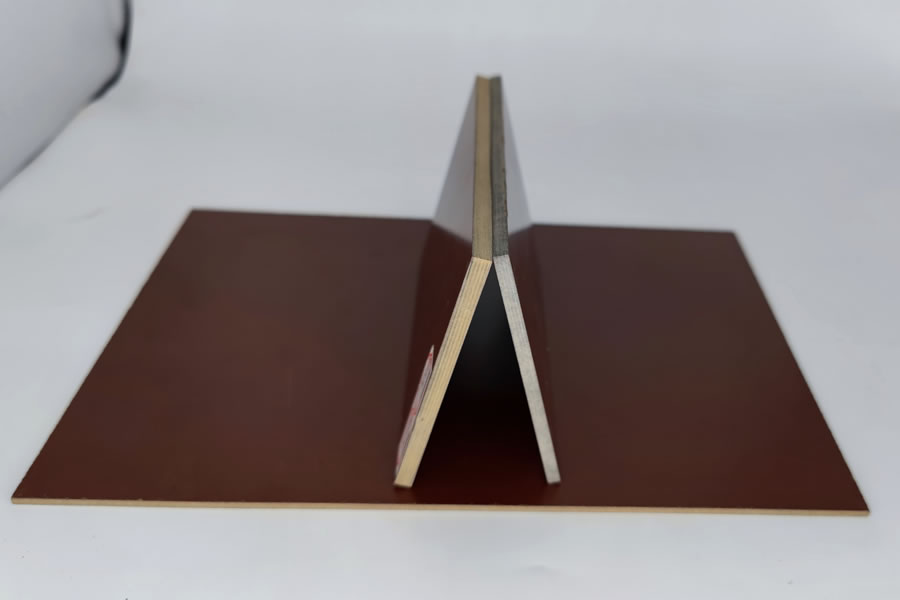

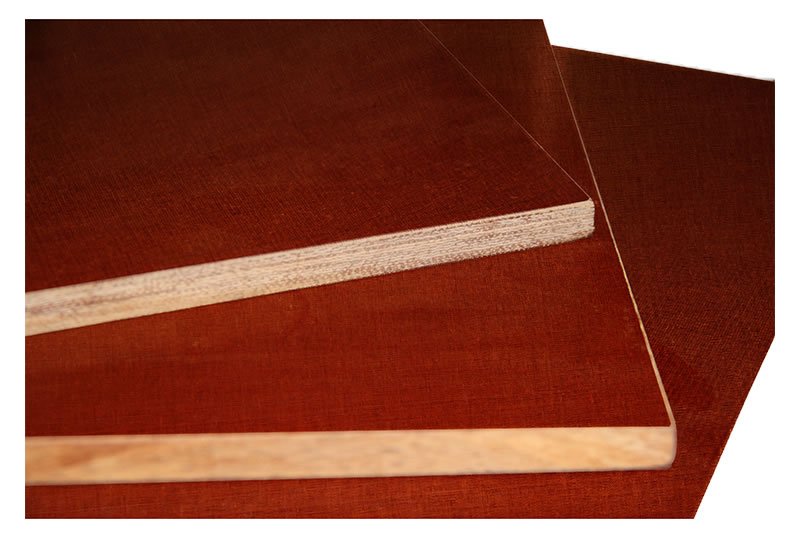

Second, the structure of phenolic paper sheets and phenolic cotton cloth boards is different

The structure of phenolic paper sheets is relatively simple, mainly composed of fiber and phenolic resin. phenolic paper sheets have better mechanical strength and insulation properties. The phenolic cotton cloth board is made of multiple layers of organic cotton and phenolic resin alternately laminated. Phenolic cotton cloth boards have better thermal insulation, sound absorption and corrosion resistance and can be used in construction, ships, automobiles and other fields.

Three, the performance of phenolic paper sheets and phenolic cotton cloth boards is different

Because the use of wood or plant fiber as raw materials, phenolic paper sheets have good mechanical strength and insulation properties, and compressive strength and impact resistance is good. Phenolic paper sheets can be used in power equipment, electronic instruments, machinery manufacturing and other fields.

In addition to good mechanical strength and insulation properties, phenolic cotton cloth board also has excellent thermal insulation, sound absorption and anti-corrosion properties. It can be used in construction, ships, air conditioning equipment and other fields.

Fourth, the application scenarios of phenolic paper sheets and phenolic cotton cloth boards are different

Phenolic paper sheets is often used in power equipment, electronic instruments, machinery manufacturing and other fields. The phenolic cotton cloth board is mainly used in construction, ships, automobiles, air conditioning equipment and other fields to meet the requirements of heat insulation, sound absorption, anti-corrosion and other aspects.

Phenolic cotton cloth boards and phenolic paper sheets each have advantages and disadvantages, and the specific choice depends on the use scenario and needs.

Phenolic cotton cloth board is made by soaking cotton cloth with phenolic resin, drying and hot pressing. It has the following characteristics:

Smooth surface: It has good processing performance and can be processed into various parts by lathe processing, stamping, trimming, drilling, sawing and milling methods .

Good electrical performance: It has good electrical performance and stable voltage resistance at medium temperature .

Stable quality: Stable product quality, easy to process .

Phenolic board usually refers to phenolic laminated board. It has the following characteristics:

Lower density: the density is about 1.35g/cm³, half that of aluminum .

Good processing performance: It can withstand sawing, drilling, turning, milling, planing and other processing. And processing should not appear cracks and slag .

Chemical corrosion resistance: It has good chemical corrosion resistance and can resist organic solvents, organic acids and dilute inorganic acids. It is suitable for many chemical equipment .

Ztelec Group is a professional manufacturer of high-quality electrical insulation materials with more than sixty-five years of manufacturing experience. If you need more product information and quotes, please contact us