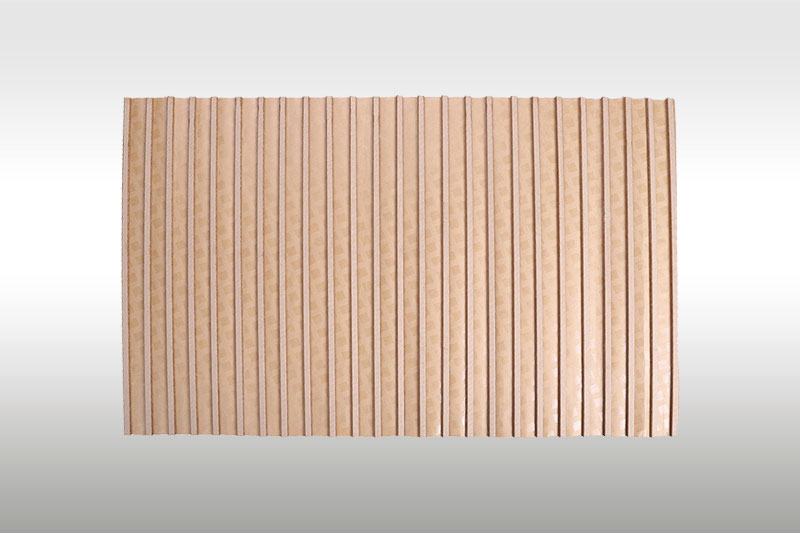

Transformer oil duct pressboard strip, as the name implies, is a paperboard strip used for insulation inside the transformer oil duct. It is mainly made of high-quality insulating pulp and has excellent electrical insulation performance and mechanical strength after special processing. In the transformer, it is mainly used to isolate components with different potentials to prevent electrical breakdown and short-circuit faults. It also plays a role in heat dissipation, support and protection of the internal structure of the transformer.

1. Material and characteristics

Material:

The main raw material of the transformer oil duct pressboard strip is unbleached sulfate wood pulp. This pulp has long fibers and few impurities. After sticky pulping and pressing, it forms an insulating paperboard with high density and strength.

Characteristics:

Excellent electrical insulation performance: The pressboard strip has high resistivity and breakdown voltage, which can effectively prevent current leakage and discharge.

Good mechanical strength: The pressboard strip has high compressive strength and tearing strength, and can withstand various mechanical stresses inside the transformer.

High heat resistance and aging resistance: The pressboard strip can operate stably for a long time in a high temperature environment and is not easy to age and deteriorate.

Low hygroscopicity and shrinkage: The paperboard strips have low hygroscopicity and shrinkage, and can maintain dimensional stability and durability of insulation performance.

2. Manufacturing process

The manufacturing process of transformer oil duct insulation paperboard strips mainly includes steps such as pulp preparation, beating, pressing, drying and curing. During the manufacturing process, it is necessary to strictly control the quality of raw materials, the degree of beating, the pressure and temperature of pressing and other parameters to ensure the performance and quality of the paperboard strips.

3. Application and maintenance

Application: Transformer oil duct insulation paperboard strips are widely used in various types of transformers, especially high-voltage and large-capacity transformers. They are cleverly arranged inside the transformer oil duct to play the role of isolation, support and protection.

Maintenance: In order to ensure the performance and life of the transformer oil duct insulation paperboard strips, regular maintenance and inspection are required. This includes checking whether the paperboard strips are aging, deformed, cracked or oily, and regularly replacing aging paperboard strips. In addition, it is necessary to keep the inside of the transformer clean and dry to prevent moisture and impurities from damaging the paperboard strips.

4. Precautions

When selecting the paper strips for transformer oil duct insulation, a reasonable selection should be made according to the type, rated voltage and capacity of the transformer to ensure that its performance meets the requirements.

During the installation and use process, the relevant standards and specifications should be strictly followed to ensure that the paper strips are accurately positioned and firmly fixed to avoid any possible damage or dislocation.

For transformers that have been in operation for a long time, regular maintenance and inspection should be carried out to promptly discover and deal with problems with the paper strips to ensure the safe and stable operation of the transformer.

In summary, the paper strips for transformer oil duct insulation play a vital role in the internal structure of the transformer. Its performance and quality are directly related to the safety and reliability of the transformer. Therefore, sufficient attention and concern need to be given during the selection, installation, use and maintenance process.